A control system which takes care of operation in automated way with minimum human intervention

Table of Contents

Introduction

In the heart of the industrial revolution and the advance technology, the word “automation” was already stirring with the best excitement. Fast forward in the today era, and industrial automation stands as one of the most transformative forces in manufacturing sector. Imagine a factory where machines, sensors, and software seamlessly work together, driving unprecedented efficiency, precision, and innovation. Welcome to the world of industrial automation, where the future of manufacturing is being written in real-time. Also if you go with the latest technology and new innovation the world is increasing its productivity and also the demand is high as we see with the increase in the population , the demand is high so to fulfill those demand the productivity need to be increase.

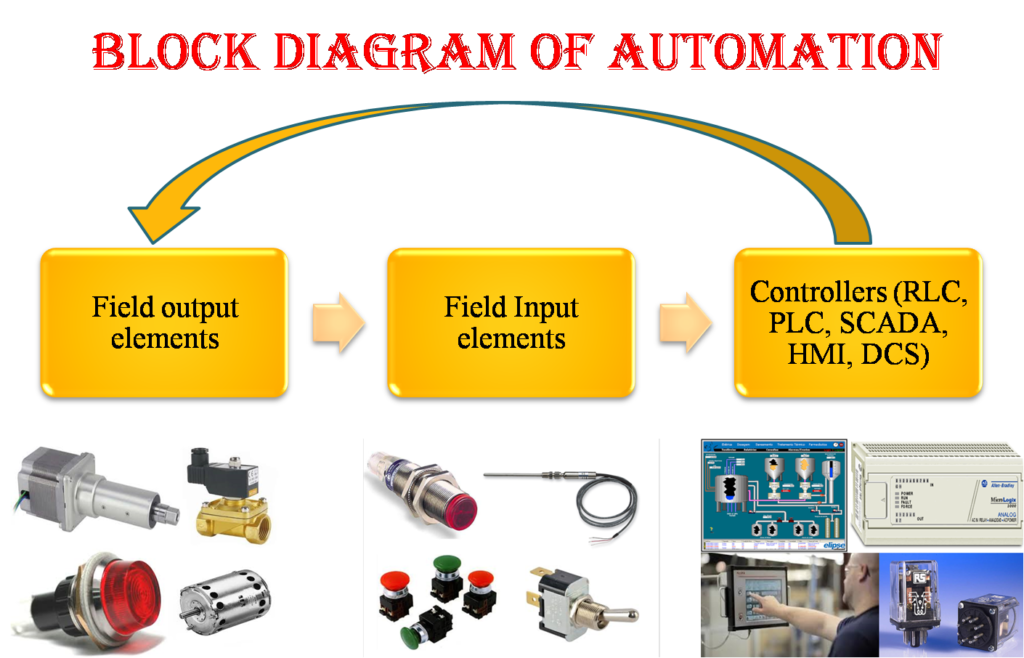

The automation is basically made up of three part with this the whole system works, if we talk about the industrial, home, factory, or building automation all having these loops with that the whole control system works. The First start with the Human control function where the human give commands with the help of the HMI (Human Machine Interface) or with the help of Computer, the data is given for the execution, then the Second step is the Delegation or the Transfer of the man power to the Machine, so the man power is decrease and the efficiency will increase with the precise work.

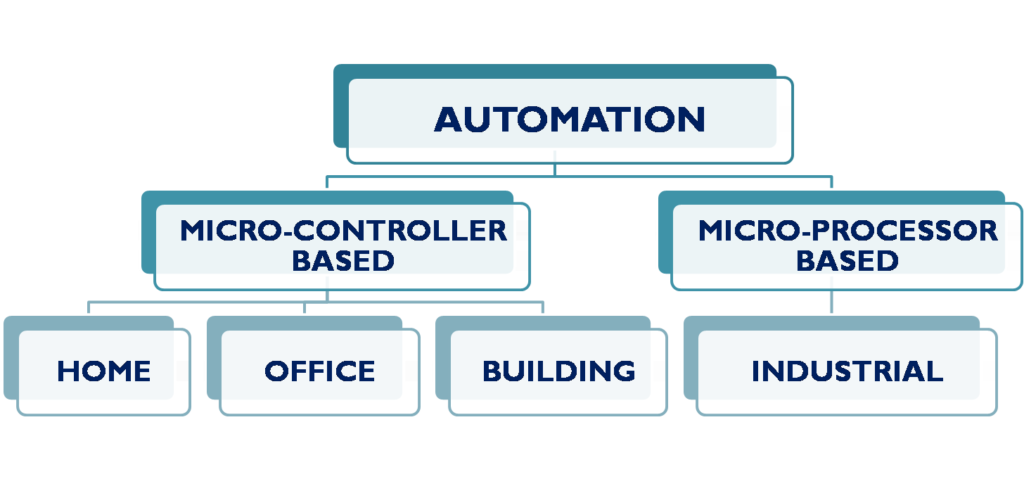

Automation Categories

Micro – Controller – As we know that the automation is categorize in the Micro – controller based and the Micro – Processor based, the automation which is functional for the particular based work or for the limited work there the micro controller based controller is used, in the office, the building the home, these are the example of home automation. In home we use automatic curtain opening and closing, for the these small controller is uses, example – Arduino , raspberry-pie etc.,

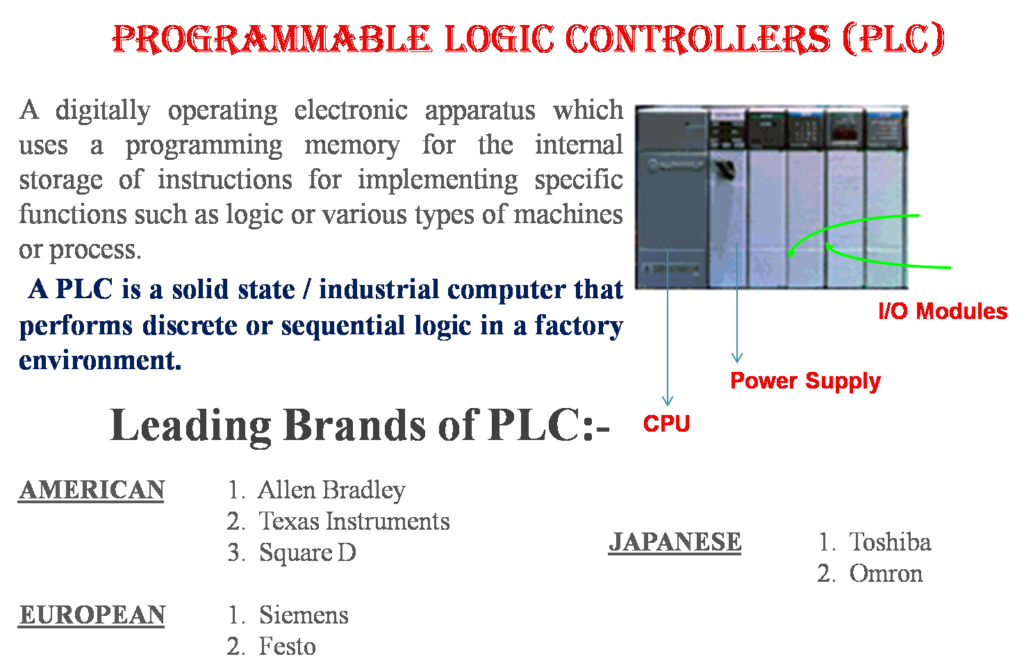

Micro – Processor – In this industry the controller is used for controlling the whole factory, like the motors, actuators, the movement of conveyer belt, counting, multiple work is done with the help of PLC, so plc is the CPU device with inbuilt Micro – processor which give he command very fast and execute the task as per the logic given.

Check out with WiFi Energy Meter

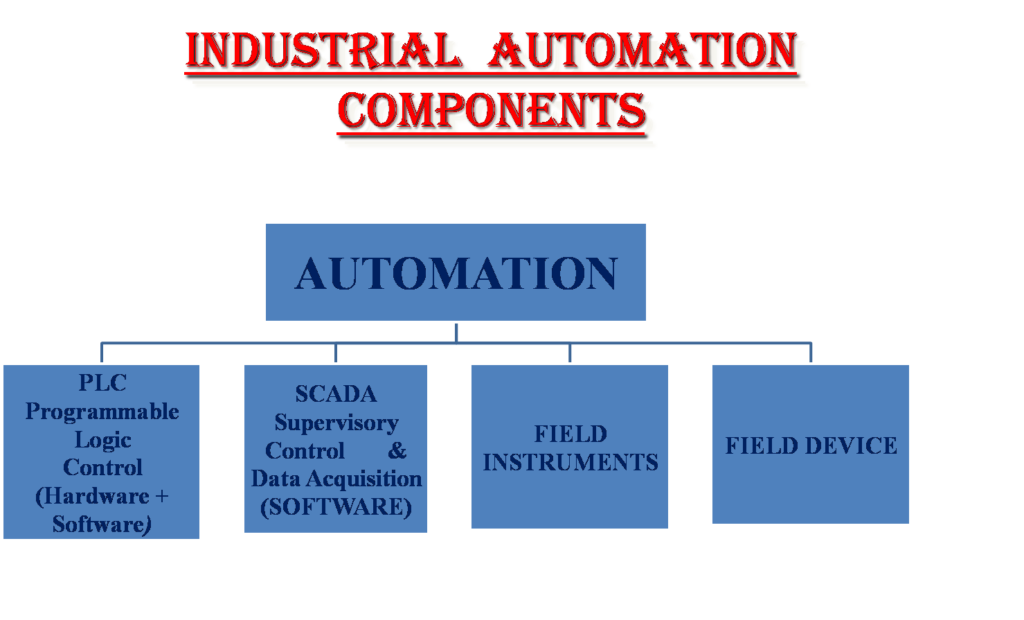

In the above figure you can see the block diagram of automation from which the whole system works and perform the task with full efficiency. The field output devices which are connected in the output side of the controller and it execute the work as per the program, the field input elements are the switches, sensors which is connected to the input side of the terminal, so we can see in the figure the third part is the controller where the RLC, PLC,SCADA,HMI and the DCS System.

Automation Components

- HMI (Human Machine Interface)

- VFD (Variable Frequency Drives & motor)

- Instrumentation

- Pneumatics & Hydraulics

- Electrical Designing & Panel Designing

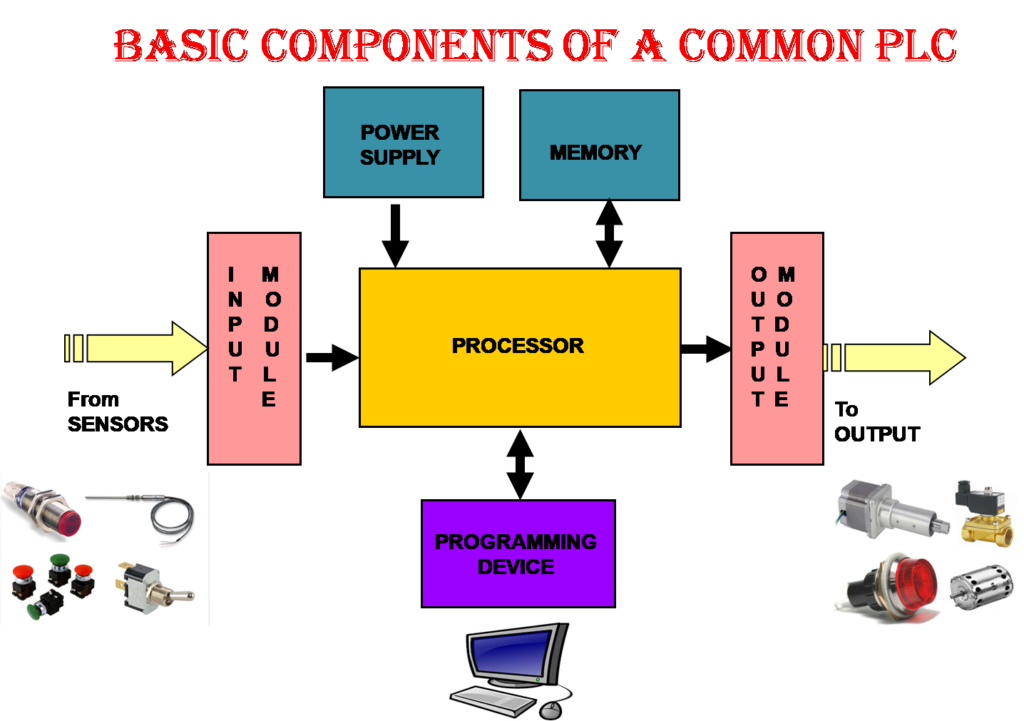

The Basic components of the plc is the input, output, processor, power supply, memory is used, with this the whole combination of plc done.

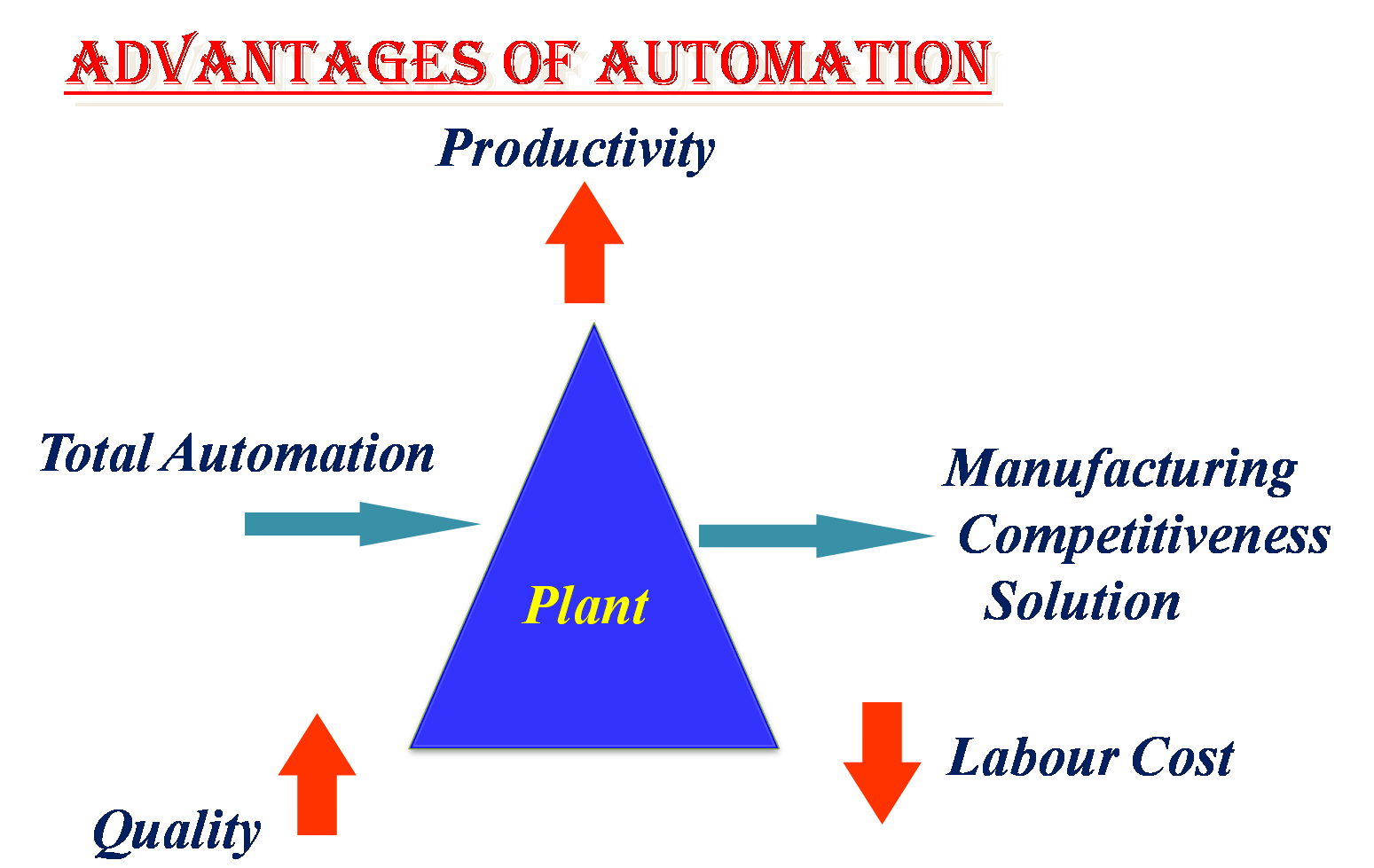

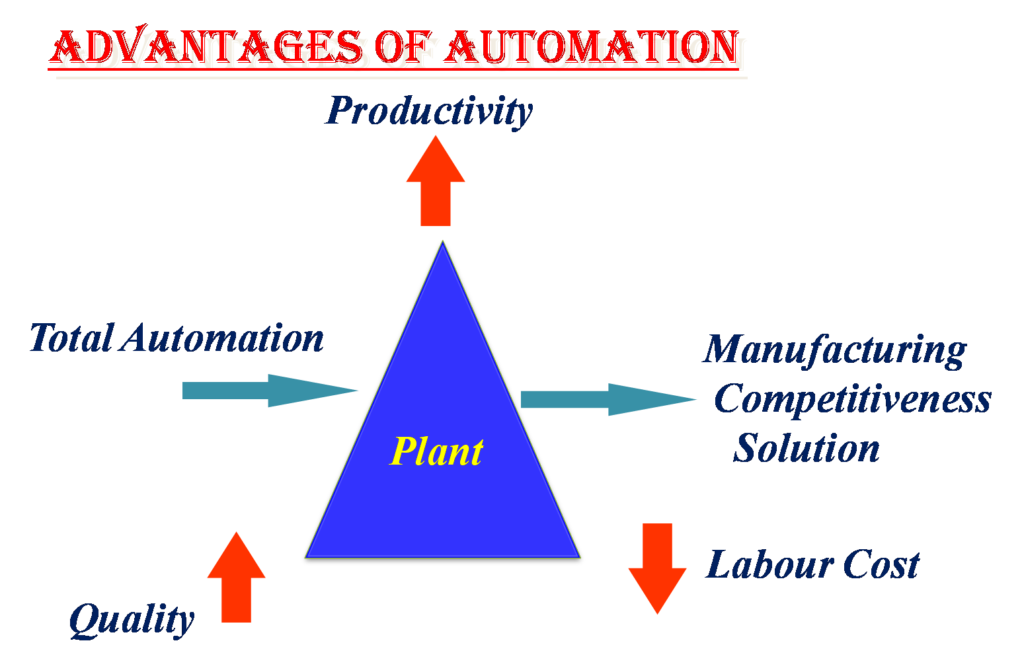

If we implement the Automation then productivity with increase, Quality will also increase, Labor cost will decrease and the manufacturing competition will be less, also if we talk about the demand and supply then at the pick time when demand increase then we have to increase the supply hence need to increase the productivity.

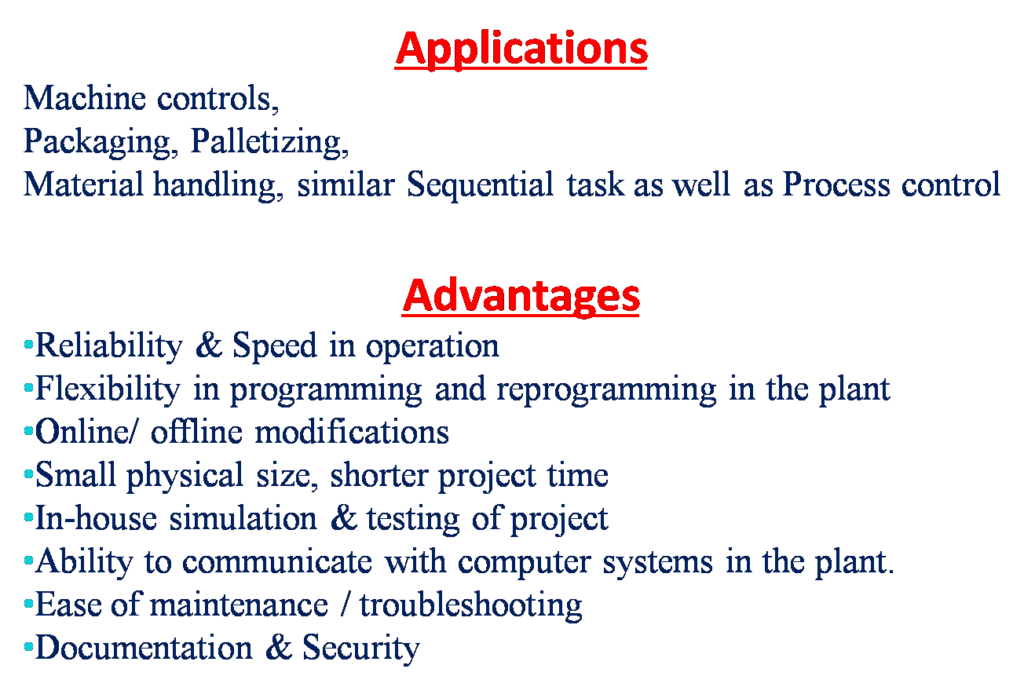

An Example of application of PLC for the basic operation of the Automatic gate control, where the gate will open once any vehicle come near and it will auto close when it pass by it.