Programmable Logic Controller (PLC) is a hardware device used to manage and control tasks in industry

Table of Contents

A Programmable Logic Controller (PLC) is a special type of digital computer, and its main function is an industrial automation solution. It comprises a CPU that controls the program and executes the other components. Inputs and Outputs are for the communication between the PLC and the external cards, the memory is for storing programs, data values, and parameters.

The PLC is programmed with the help of software and also, we can modify the program as per our uses. The power port is for the continuous power for operation, other than this is the communication port, which is used for the communication of the plc with the programming software. This connection is also done with the devices which relate to this. The PLC has specific language such as Ladder Logic, Structured text, Functional Blocks, or Instruction lists. This program for as per the logic given so it will work efficiently and reliably in the automation system.

How does a PLC work?

Processor :– The main brain of PLC is the place where the logic comes and executes as per the program, as we know for the proper functioning of any logic, like the operation of a conveyor belt in the industry, we need to move the motor with the specified speed with the sometimes delay, for this operation the logic is designed and then this operation is carried out by the processor.

Sensor:- This is connected to the input side of the PLC, where the signal is received and it gives the output command to the PLC where the field devices like Motors, and actuators are placed, the signal is received in Analog or Digital, further, this signal is forwarded to function as per the logic or the program.

Output :- After receiving a signal from the input to the PLC (Programmable logic controller), the output command is given and the operation is executed as per the logic. The output devices are like a valve, motor, pneumatic, etc.

Communication:- This is essential for the data sharing and execution, the data is shared with the SCADA to operate in get visible at the Graphics, whatever the points we discovered with the filed devices and the field instruments.

Memory:- For storing the data in the form of a program, space memory is required, so data is stored in it and it starts work as per the sequence of operation, which is fed in PLC (Programmable logic controller).

PLC Architecture

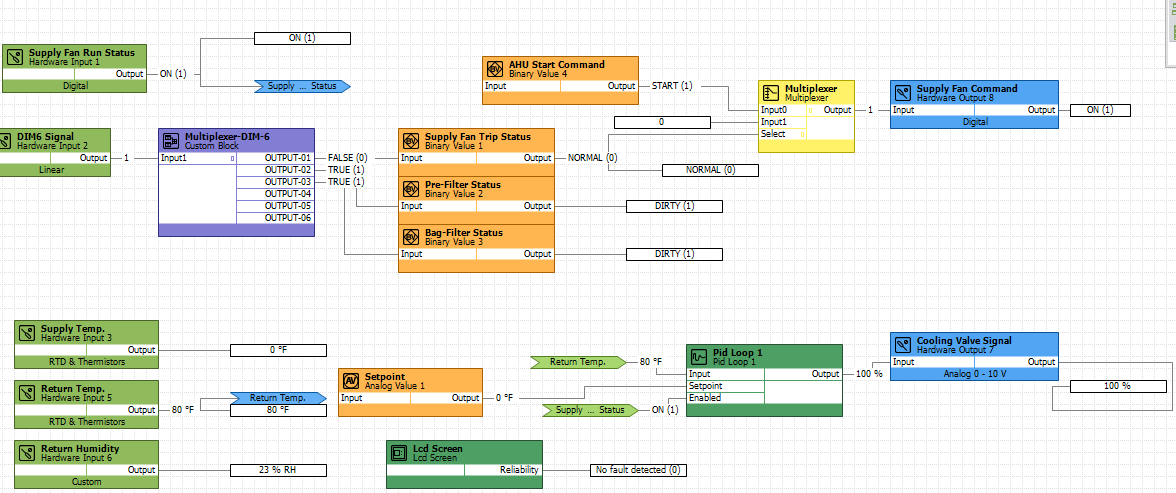

Fig :- figure of plc points

What are the application of PLC?

PLC (Programmable logic controller) use in the automation industry for the precise and fast work, let us take an example of Dairy Plant:-

What do I must have to consider while choosing a PLC (Programmable logic controller)?

There are several PLCs available in the market now. Aside from cost, we need to choose as per our requirement which is listed below based on application.

Reliability:

The operator must know the operation time since some plants run continuously for 24 hours, so service time will also increase, so choosing a reliable PLC is very important.

Environmental Conditions:

The PLC must be Environmentally friendly, which should not affect nature.

Cost and Total Cost of Ownership:

Identify the number of points you require in that project, so adding the points will increase or decrease the overall cost, it also includes the license of software. SO very important for the contractor to give the quote that is best in the market and also cheap, so the client must satisfied and confirm the order.

CPU Speed and Response Rate:

Always select the latest version of PLC, with the latest software, and also check the speed of operation and response, since the industry requires very fast operation.

Memory Capacity:

For future requirements and the increase in the number of the extra input-output cards, must select the plc with the added memory slot.

Redundancy:

This is important for the PLC to have redundancy since the debugging must be very fast so the system will run very smoothly.

I/O Requirements:

As I discussed earlier always select the PLC, where you can add the card for future requirements. So with the same controller, you can have an operation.

Communication Protocols:

The protocol is important for the device communication, select the better protocol PLC as per the requirement, like Bacnet is used basically for the BMS, Modbus, Lonwork, etc.

Compatibility:

If you work for the existing system, you must know whether the controller is compatible with it or not, concerning the protocol or the device’s communication.

Special Actions:

If you need any special operation like the motion sensor or any scheduling so choose special type of PLC.

nice